NAOJ GW Elog Logbook 3.2

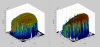

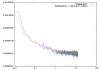

I found the solution to the heat equation in this article and I calculated numerically using Matlab.

I show the solution of the heat equation for an absorbing fused silica medium.

- oscillating pump gaussian beam size 70micron

- oscillation frequency 430Hz

- absorbing thickness 10micron

- absorbed power 0.1mW

- fused silica thermal parameters

- scale in Kelvin

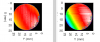

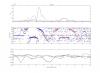

I made two resolved maps of the entire surface of the reference sample (200micron scan step) where the surface is behind the pump (flipped sample). One scanning along X axis (left in the image) and one scanning along Y axis. It shows that there are little fluctuations and they are a bit larger perpendicular to the scan axis. This happens for both maps. This means there are some long time power fluctuations. Maybe it shows more clear in the second attached image where there is only a 2D map.

There is also a relevant difference between the center of the sample and near the edge, the maximum is near the center, and the difference depends on the map. Still to be understood.

Four 30 out of 36 washed pieces of the OSEMs, the coil wires are fixed to their bodies by a vac seal, and now being cured (for one or two days) in the ATC ISO-1 clean booth. I need more vac seals.

I use nozzles but the viscosity of the vac seal is so high that my grip now reduces forces..

The 30 pieces of the coil bodies are "doubly" packed into clean polyethylene packs (made in a class-100 room, the provider said) in the ATC ISO-1 clean booth. Will be sent to KEK soon.

The Remaining 37 OSEMs are now being cured in the ISO-1 clean booth in the ATC multipurpose experimental room!

Don't touch them for a couple of days.

Previously I did this 30 OSEM coils, and today 37coils, that means there will be 67 OSEMs in total. The number is sufficient for iKAGRA, but not for bKAGRA, as at least 70 OSEMs will be required for the bKAGRA (PRM, PR2, PR3, BS, SRM, SR2, SR3).

There are some OSEM coils washed or unwashed and used for trials of several process for the assembly, and they should be added to the number to fulfill the required numbers.

37 OSEM coil bodies are now packed into clean bags. (Akutsu, Fujii)

Plus 5 OSEM coil bodies are washed (by ethanol), and then 67+5 = 72 OSEM coil bodies will be available in the end.

I measured some maps of the Surface reference sample.

I order to compare and join different areas of the sample and in order to process datas I wrote a matlab script that read the .txt file the program uses to store measurements datas.

The map is made scanning many lines, the scan direction used here is the X axis. In the plot we can see some fluctuations that are bigger alog the Y axis. My guess is that long time fluctuations of the pump power cause this. We can also recognize the edge of the sample by the lowest signal at (x,y)=(36,30.5)

I made two resolved maps of the entire surface of the reference sample (200micron scan step) where the surface is behind the pump (flipped sample). One scanning along X axis (left in the image) and one scanning along Y axis. It shows that there are little fluctuations and they are a bit larger perpendicular to the scan axis. This happens for both maps. This means there are some long time power fluctuations. Maybe it shows more clear in the second attached image where there is only a 2D map.

There is also a relevant difference between the center of the sample and near the edge, the maximum is near the center, and the difference depends on the map. Still to be understood.

I wanted to understand the big difference between the absorption peak in the configuration where the pump is entering in the sample by the absorbing surface and the other configuration where the pump is entering the sample by the not absorbing surface (flipped sample). So I made again a calibration and also a calibration with the flipped surface reference sample and I found a calibration factor R=17 1/W (flipped) and R=13 1/W (not flipped). For the not flipped sample I made a calibration history in this post and I found a mean calibration factor R=11 1/W with fluctuatoins of 10%. I don't understand why R changes so much.

If we calculate the LMA15033 absorption with those R factors we get 22ppm for the flipped surface and 14ppm for the not flipped surface.

I conclude that the recommended wedge angle is 20m rad.

Akutsu and Takahashi washed 36 pieces of OSEM coil bodies with acetone in a ultrasonic bath. They are now located at the ATC ISO-1 clean booth to dry. Later, Akutsu will put vac seals to the coil to fix the wire edges, and pack into clean bags, and send to KEK for baking.

The number is just determined by the fact (1) PR2, 3, BS OSEMs are urgent, so 30 pieces are needed, (2) the ultrasonic bath can contain 12 pieces at once.

- Five pieces of the OSEM coil bodies (wires are wounded) are washed with acetone in a ultrasonic bath (40degC, 20mins). The wires' edges are not fixed to the coil body because Takahashi-san pointed out that the vac seal could be removed by acetone.

- A PD(S1223-01) and a LED (TSTS7100) are also washed in the same manner. I'll check if their performance would decrease (increase?) or not.

Results

Conditions:

- The washed and non-washed PDs are different ones.

- The same LED's intensity noises are measured before and after the wash.

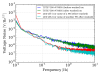

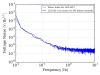

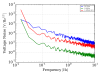

The attached graph shows the washing would not affect the performance; it's only one sample, so we still lack a statistics, but we can probably say they can tolerate the ultrasonic washing.

About the PDs, noises with PDs are the same level as the 35670A at their inpur ranges. The mechanism why the input ranges are different for the two measurements are unknown, but one thing: the Okt circuit and LEDs and PDs are connected by crocodile clips (alligator clip, whatever), and the noise level is very senstive to the arrangement of these wires!

According to the graph, it appears the washed one becomes better than unwashed one, but the measurement are the same level as the measurement noises, so we cannot say such things.

I checked the temperature inside the rack after about 24 hours. It was 23.9C. The temperature raise is too small. I will look for a way to generate more heat (heater) in a controlled way (slidac ?).

At some point, we have to put the instrument control system racks in the humid environment of the tunnel.

I borrowed a plastic cover from DGS and put it on one of the racks. Then I turned on the system. I also put a temperature meter.

I will leave it like this until tomorrow to see if the temperature goes up high enough (above 30C).

If the temperature is high, we can expect the local humidity to drop accordingly. So we can move the rack to the field.

Right now, the wrapped rack is sitting in front of the shutter.

I checked the temperature inside the rack after about 24 hours. It was 23.9C. The temperature raise is too small. I will look for a way to generate more heat (heater) in a controlled way (slidac ?).

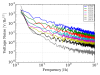

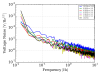

In order to see how the intensity noises of the LED (TSTS7100, not OP232) will change, I slightly modify the Okt driver. A trimmer (CT-94EW500-ohm) is attached to the driver so that the LED current can be variable. The attached graphs are the measurement results. According to the results, when the DC powers is over a certain level (in this case it is around 4Vdc... note that which is caught by the OSEM prototype setup, not the naked direct input power to the PD from the LED) , the intensity noises are not proportional to the DC intensities.

The followings can be said:

(1) because we don't want to input such a large current into vacuum, and the lowest usable DC current should be supplied to the LED (I still did not measure the trimmer's resistance). In terms of this, the DC current should be tuned to make the PD output to 1Vdc~2Vdc.

(2) If you are worrying about the other noises (scattering light of 1064nm, analog-to-digital noise, and ...) would cover the OSEM signals, the calibration factor (or sensitivity) of the OSEM should be kept high, meaning larger DC current to LED would be better. Then the maximum PD output would be (this is only my recommendation/suggestion) around 4Vdc.

My recommendation:

I like to setup the PD output to 1.5Vdc, which would be sufficient.

The cooling-down has been finished at Friday night. The final temperature is 4K, just as given also by the company.

The overall duration of cooling down with full vacuum is about 55 hours.

I started the warming-up today in the morning just by switching off the cryo-cooler.

The temperature curve is being recorded again.

Attached are a photograph of the temperature controller this morning and the cooling-curve as taken during the test.

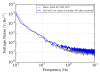

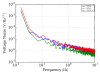

The attached graph shows noise level of two OSEM setups; with a satellite box (Sat) and with a test driver (Okt) made in NAOJ (design based on the Sat, but Akutsu chooses necessary/sufficient parts what he thought, and Okutomi made). Those two circuits supply different amount of DC current to the LED (TSTS7100). Exactly the same LED and PD combination is used for the measurements.

(0) The measurement systems's noise level (raw voltage noises) for both cases when the LEDs were turned off are in the same order of magnitude. (I don't mention the PD's noises here, and it will be mentioned in (1). I'm mentioning about the noise of measurement system with the range which is used when the PD circutis are measured. The second attached graphs are the raw voltage spectra (V/rtHz vs Freq), and showing this. S70908 (for the satellite box) measurement was done with 6.3mVpk range, while S70905 (for the Okt driver) was 7.95mVpk, and the ratio can explain the relation of both measurement noises) The difference shown are due to the difference between calibration factors (V/m) for the cases.

(1) Why are the PD noises (LED off) such different...?? For the Okt test driver, OP27G is used; for the satellite box, it seems OP2177. The transimpedances are the same (38.3k Ohm).

(2) The LED's intensity noises do not appear proportional to the DC powers. The displacement noises should be the same level if it is proportional.

(3) Additional Note: the satellite box's output of PD driver has a relatively large offset like 20mVdc even without any PDs are not connected, and which is not observed in the Okt test driver. I just add a 5.6k Ohm (by clips) parallely to the 38.3k Ohm and observed the offset decreases accordingly (38.3//5.6 = 4.88kOhm, and 38.3/4.88 = 7.84 times), and the same happens for the power spectrum of the intensity noise... so the offset would come from the opamp's current offset and current noise-like things. As was reported, some polarized capacitances are directed wrong, so some opamps would have malfunctinos now... I checked a OP2177's data sheet but cannot find descriptions on the current noise around low frequencies. The current offset is described but it is too low to explain what are happening here.

(4) Next I decied to use only the Okt test driver's PD circuit for evaluating what's going on the LED noise. With this driver, the larger (and non-proportionally large) noise of the LED driven by the satelite box is confirned again. The current to the LED would be now estimated to 88.3mA (the feedback loop makes 200//33 Ohms should be 2.5V)with the satellite box, and 8.3mA (the feedback loop makes 200+100 Ohms should be 2.5V) with the Okt test driver. This could explain, at least order, the rate why the output is 8.92Vdc for the satellite box and 740mVdc for the Okt. The intensity noise spectra are, however, not proportional to those DC voltages or current to the LEDs. Need to be more investigated; the goal would be to find the LED current setup in which the intensity noise would be slightly higher than the PD driver's noise; fortunately, I think the Okt circuit condition is very closed to this goal!

Anyway, generally speaking, I recommend to use a FET-input opamp for a transimpedance amplifier application like the PD driver circuit... as I did for the oplev QPD driver for KAGRA.

In order to see how the intensity noises of the LED (TSTS7100, not OP232) will change, I slightly modify the Okt driver. A trimmer (CT-94EW500-ohm) is attached to the driver so that the LED current can be variable. The attached graphs are the measurement results. According to the results, when the DC powers is over a certain level (in this case it is around 4Vdc... note that which is caught by the OSEM prototype setup, not the naked direct input power to the PD from the LED) , the intensity noises are not proportional to the DC intensities.

The followings can be said:

(1) because we don't want to input such a large current into vacuum, and the lowest usable DC current should be supplied to the LED (I still did not measure the trimmer's resistance). In terms of this, the DC current should be tuned to make the PD output to 1Vdc~2Vdc.

(2) If you are worrying about the other noises (scattering light of 1064nm, analog-to-digital noise, and ...) would cover the OSEM signals, the calibration factor (or sensitivity) of the OSEM should be kept high, meaning larger DC current to LED would be better. Then the maximum PD output would be (this is only my recommendation/suggestion) around 4Vdc.

My recommendation:

I like to setup the PD output to 1.5Vdc, which would be sufficient.

The first cycle of cooling the tank has begun today.

After having some trouble with the calibration of the temperature controller and a sudden (and still unexplained) problem with the pressure meter, we are now cooling the tank.

The rate of cooling is now approximately 0.07 K/min at an inside pressure of 2.2*10^(-4) Pa.

With this rate, the cooling down to 10 K will last at least 2,5 days (even more is expected when the temperature falls below 70 K and freeze-out of the remaining gas appears).

I think of using He gas in the future that could be injected into the tank for increasing the effectivity of the cooling process.

Attached is a photograph of the temperature and the pressure controller at the beginning of the cooling cycle, right after the cool-down has started.

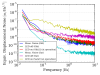

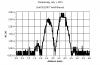

I measure the surface absorption peak of LMA sample #15033 at different powers.

The first plot shows the scans along Z axis

The second plot shows AC signal peak at the surface as a function of the pump power.

The third plot shows the proportionality as a function of the pump power

Last friday (3rd July) I cleaned both surfaces of LMA coated sample #15033 (abs=12.8ppm) as shown in the first picture using the first contact polymeric optics cleaner.

I measured the absorption of the sample along Z axis. I made scans of 10mm in order to see both surfaces. The sample thickness is 6mm.

I made a scan (blue line in the second figure) and then I flipped the sample in order to see also the other surface (black line) and I notices a strange peak, then I moved the sample 0.1mm along Y axis and I repeated the scan (red line). The black line shows an absorption that has a not usual pattern. I guess it is because of some scrach on the surface, because just 0.1mm apart it doesn't show.

This monday (6th July) I made again the measurement of sample and of flipped sample, (third picture). It shows a variation among the two surfaces of a factor of 2. Maybe it is just a fluctuation of the absorption value because flipping the sample we never go back to the same X,Y position.

I wanted to understand the big difference between the absorption peak in the configuration where the pump is entering in the sample by the absorbing surface and the other configuration where the pump is entering the sample by the not absorbing surface (flipped sample). So I made again a calibration and also a calibration with the flipped surface reference sample and I found a calibration factor R=17 1/W (flipped) and R=13 1/W (not flipped). For the not flipped sample I made a calibration history in this post and I found a mean calibration factor R=11 1/W with fluctuatoins of 10%. I don't understand why R changes so much.

If we calculate the LMA15033 absorption with those R factors we get 22ppm for the flipped surface and 14ppm for the not flipped surface.

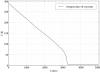

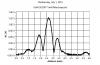

We have finished the third cycle of pumping and observing the pressure after closing the gate valve on the cryostat in the ATC.

The results, compared with the other two cycles and the initial measurement, can be seen in the attached pictures.

Obviously, for the pumping, we can not get the vacuum that has been reached in the initial measurements but we could confirm the data from the second cycle with a final pressure of approx. 6*10^(-4) Pa after 60000s of pumping. The initial cycle reached approx. 4*10^(-4) Pa.

Again, the vacuum is by far better than in the first cycle after the cryostats repair.

The rising of the pressure after closing the gate valve follows quite exactly the development of the initial cycle. No important differences could be observed.

We also checked the connections for the temperature controller and are ready to braze the cabels on the respective connectors (will take only 30min, or so).

From our understanding, we are ready for doing the test of the cryogenic system and will start it on Monday, probably.

I put the surface calibration sample in the big sample holder and I found the position of the sample surface along the Z axis is about 8mm different with respect to the little reference sample holder. This just means the scan should start from Z0=12mm instead of Z0=20mm.

I put the sample of LMA in the holder and I attached the holder to the translation stage, I acquired 1hour of noise and it turns out to be 18microV std with no spiky noise. This is means the presence of the sample holder doesn't increase the noise.

I acquired the scan of the coated sample they gave me at LMA (sample 15033, they measured abs=12.8ppm @1064). Pump power = 171mW (LD current = 1.2A)

The first image shows the scan along Z axis of the sample. We can see two peaks and this is not the coating absorption patter we see in the calibration. The reason is that we are looking at the surface which doesn't have a HR coating

The second image shows the scan along Z axis of the flipped sample, in order to see the right HR coated surface. It has a pattern very similar to the calibration scan, a high peak at the surface and the two smaller peaks of diffraction effects.

The absorption calculated from this measurements and the calibration factor with the reference sample we have (surf_abs = 22%) gives 107ppm, almost a factor of 8 higher than the nominal value (12.8ppm). We are understanding the meaning of this. We will check the calibration factor, how the software filtering works and how clean is the surface of the sample.

The formula is Abs=AC/(DC*Power*R) where R is the calibration factor, it has a value of 10+/-1 and it is calculated with the surface reference sample calibration (abs=22%).

I wrote an OSEM assembly procedure; please have a look!

http://gwdoc.icrr.u-tokyo.ac.jp/cgi-bin/private/DocDB/ShowDocument?docid=3762

Today (Monday 29th) I acquired an hour of noise in the exactly same condition and I found 18microV of noise and no spiky noise at all. The only thing that changed since last time is that the system has been at rest for the weekend, about 48 hours.