NAOJ GW Elog Logbook 3.2

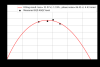

What I did: estimated Q factor

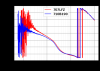

I tryed to measure Q factor of Roberts Linkages that resonant frequency is 0.67Hz by ring down curve.

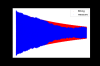

When I estimated Q factor, I used the data from 500s to 1400s (just Fig 2).

Estimated Q factor is 5.97×10^3.

Blue points are measurement and red points are fitting.

Vertical axis is read out of photo sensor that can detect displacement, horizontal axis is time.

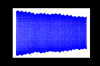

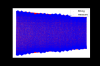

Fig 1 is over view of the ring down curve.

Fig 2 is the data that is used for estimating Q factor.

Fig 3 is over view and fitting results.

Fig 4 is the ring down curve that is used for estimating Q factor and fitting results.

Fig 5 is also the ring down curve and fitting results from 600s to 620s.

Yohei,

I started to built a new set up of the speed meter experiment.

What I did:

I put a QWP and HWP in front of the source laser (Mephisto, Innolight), mazimizing p (holizontal) polarization.

Then, I put a Faraday Isolator (FI), optimizing its extinction ratio.

I measured the transmissivity of the FI:

Input = 10.3 mW,

Ouput = 9.3 mW,

Transmissivity = 90.3 %.

When measuring the beam power by a power meter, I attatched a ND filter, ND=2.0. From this value, the source lase power can be extimated as ~ 1W, keeping its original value.

I evacuated the duct with the large RP so as to be lower than 0.1mbar. After that, the GVs between the pumps and the duct were opened except for the south end.

[Marc, Michael, Yuhang]

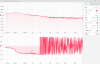

We measured FIS with various green power as reported in figure 1.

However, one issue was that CC1 and CC2 error signal were extremely glitchy with every few seconds a huge increase in their levels.

Note that to speed up the FIS recovery we did not tune too carefully the various servo gain.

We will do it soon and also investigate PLL phase noise.

We suspect this is the reason why we can not see improvement on the phase-noise (fig2).

Today, all (four) pump units along the south arm have failed. I supporsed that the dry-pump replaced yesterday in the south end faild at first, then other pumps also went to stop. The pressure of the arm duct increased to 20mbar. The dry-pump in the south end was broken with "ALM05 MP STEP", The other pump units were recovered. Since the pressure of the arm duct is too high, the GVs between the pumps and the duct are closed. It is necessary to evacuate the duct with the large RP so as to be lower than 0.1mbar.

What I did: I fited the transfer function of Roberts linkages, and estimated the resonant frequency and Q factor of it.

I analyzed the transfer function of Roberts linkages, and try to estimate the resonant frequnecy and Q factor of it.

When I estimated the resonant frequency and Q factor, I do it separately. The reason are as follows.

First, When I measured the transfer function, the gain around the resonant frequency is crashed by out of the linar range of the photo seosor. So I need to omited these bandwidth. Meanwhile I need the bandwidth of resonant frequency when I try to analyze Q factor.

From the above situation, I estimated the resonant frequency and Q factor separately.

The result were as follows. The pictures were also attached.

| Fig1 | Fig2 | Fig3 | |

|

position of center of mass[mm] |

-7 | -20 | -41 |

| resonant frequency[Hz] | 0.41 | 0.50 | 0.67 |

| Q factor | 2.0e+06 | 2.8e+08 | 5.4e+06 |

Position of center of mass means lenght from suspension point to center of mass vertically. Negative means that center of mass is below suspension point.

Estimated Q factor are so big and strange, and I thought It was caused by not enough time resolution.

What I will do: I measrue Q factor by ring down curve fitting.

[Marc, Michael, Yuhang]

First we realigned p-pol, BAB and green into OPO.

For BAB, we installed a power-meter before the homodyne.

We restarted the homodyne power supply (-19V, 0.06A) and confirmed the usual BAB transmission from OPO (~400 uW or ~200mV on homodyne sub DC).

We balance the homodyne using LO beam.

We realigned LO and BAB into AMC.

Then, we checked the OPO non-linear gain with MZ offset 4.2V.

We found T = 7.122 kOhm and p-pol freq = 180 MHz was maximizing amplification.

We measured with green (26mW) maximum of BAB of 1.04V while wihtout green it was 0.186V meaning a non-linear gain of about 5.4.

We lock CC1 and CC2 using the DDS3 config saved as '20230406_dds3'. Note that we found out that DAC1 and DAC3 cables of DDS3 are swapped. We should remember to modify accordingly the DDS3 config after reconnecting properly the cables.

Using the new SR785 we measure squeezing, anti-squeezing, shot-noise, homodyne noise and SR785 noise as attached in figure 1.

Note that the data are saved in .78D. To convert them into text file we have to save the data into the folder ./python/conversion and then use the command 'SRTRANS /Oasc /D SHOTN2.78D SHOTN2.txt' where SHOTN2 is the filename to convert.

Because we had to 'randomly' tune various gains to speed up debugging, we have some noise structure about 4 kHz. We will remeasure the OLTF to better tune their gains.

In any case, we measured about 5.9dB squeezing and 11.5 dB anti-squeezing !

This is compatible with our loss estimate in the wiki. We will measure squeezing again to see the EOM replacement effect on phase noise.

We found the IRMC transmission was 1.28mW while it was about 2mW in the past.

We remove a quite transparent square ND filter and could recover about 1.8 mW transmission.

We tried to tweak a bit alignment (both PBS and lens before the IRMC) but it did not change the transmission.

[Marc, Michael, Yuhang]

As reported in previous elog (eg 3189), the error signal of GRMC is about 10 times smaller than the nominal value.

We checked the RF signal used to lock about found that it is about -36dBm.

So we decided to use an unused amplifer from the amplifier rack (previously used for EOM FC/GRMC and providing 20.8 dB amplification).

After that, our RF signal is about -9dBm.

With this higher RF power, the error signal is now 800Vpk and we can lock GRMC and MZ with no particular issue.

The GRMC transmission with MZ offset of 4.2V is now about 26mW (25mW nominal).

I found that the dry-pump (ACP15) in the south end has failed. I replaced it with the spare pump (DSP500).

Today, all (four) pump units along the south arm have failed. I supporsed that the dry-pump replaced yesterday in the south end faild at first, then other pumps also went to stop. The pressure of the arm duct increased to 20mbar. The dry-pump in the south end was broken with "ALM05 MP STEP", The other pump units were recovered. Since the pressure of the arm duct is too high, the GVs between the pumps and the duct are closed. It is necessary to evacuate the duct with the large RP so as to be lower than 0.1mbar.

I evacuated the duct with the large RP so as to be lower than 0.1mbar. After that, the GVs between the pumps and the duct were opened except for the south end.

I started the SIPs between the NM2 and the mid point in the south arm. The power supply #1 (DIGITEL MPC) drived "N-S P1" and "N-S P2", and the power suply #2 (DIGITEL 1500) drived "N-S P3"(photo) and "N-S P4". Applied voltag and current were changed as follows.

[Just after starting]

| N-S P1 | N-S P2 | N-S P3&P4 | |

| Voltage [V] | 5640 | 5510 | 5200 |

| Current [mA] | 4.3 | 9.6 | 5.4 |

[Ater 2 hours]

| N-S P1 | N-S P2 | N-S P3&P4 | |

| Voltage [V] | 5840 | 5810 | 5300 |

|

Current [mA] |

0.6 | 1.4 | 1.7 |

I checked the voltage and curent in the SIPs today.

| N-S P1 | N-S P2 | N-S P3&4 | |

| Voltage [V] | 5890 | 5980 | 5400 |

| Current [mA] | 0.45 | 0.83 | 0.88 |

I started the SIPs between the EM2 and the mid point in the south arm. The power supply #3 (DIGITEL 1500) drived "N-S P5" and "N-S P6", and the power suply #4 (DIGITEL MPC) drived "N-S P7". Applied voltag and current were changed as follows.

[Just after starting]

| N-S P5&P6 | N-S P7 | |

| Voltage [V] | 5000 | 5720 |

| Current [mA] | 20 | 4.4 |

[After 3 hours for P5&P6 or 1.3 hours for P7]

| N-S P5&P6 | N-S P7 | |

| Voltage [V] | 5200 | 5980 |

| Current [mA] | 0.6 | 0.8 |

I checked the voltage and curent in the SIPs today.

| N-S P5&6 | N-S P7 | |

| Voltage [V] | 5200 | 5930 |

| Current [mA] | 0.2 | 0.4 |

I started the SIP "N-S P8" near the south end. Applied voltag and current were changed as follows.

[Just after starting]

| N-S P8 | |

| Voltage [V] | 5910 |

| Current [mA] | 0.8 |

[After 3 hours]

| N-S P8 | |

| Voltage [V] | 5910 |

| Current [mA] | 0.4 |

Yuhang, Marc, Michael

The lock of both the p-pol and CC phase locked loops was recovered.

Details

Yuhang adjusted a bit the fiber coupling and noticed a bit of an issue with touching something somewhere and the fiber signal immediately disappearing.

Yuhang adjusted the ML-ppol fiber coupler position while Marc and I looked a bit at the green mode cleaner. The mode matching is 95.4% but the error signal is also a bit low, about 120 mVpk (in the past it was 10x larger). This situation is similar to the IRMC and SHG. We seem to be losing a bit of power from the transmission of the BS90/10 to the input of the MZ. The beam seems quite large and passes close to a mirror post on the way to the MZ input.

Eventually we certified a satisfactory level of fiber coupling for all 4 fibers. Taking the signal from the fiber PD shows a 45 MHz peak at -20 dBm and we could see some optimisation on the spectrum analyzer using the half wave plate.

We were a bit confused about which DDS RF signals required an attenuator before injection to the PLL servo, and by chance found that the DDS3 DAC3 is controlling the p-pol local oscillator - it should be controlling homodyne LO, with p-pol LO coming from DAC0 - with our recent PLL issues we didn't have the correct PLL LO frequency (was 7 MHz, should be ~ 20 MHz) and didn't notice this cause until now. But we decided to leave it for now and just try locking the PLL with the DAC3 port.

We found that some ad-hoc DC blocks (grey boxes on the bottom of the rack labelled #4, #5, #6 etc) used for monitoring the PLL signals were improerly connected. So we double checked all the connections coming from the fiber PDs and confirmed the proper placement of signals going to the "BEAT" port on the servo, and the "MON" wires near the spectrum analyzer. Then we confirmed the sign of the signal on the PLL software and eventually could lock p-pol PLL with fast and slow loops.

For the CC p-pol, we discoverd some silly mistakes like mixing up the CC/p-pol lasers and a disconnected signal wire. Then we saw that the CC LO PLL signal is very large (14 dBm) so we put the -12 dB attenuator back in. There was some issue again with the PLL software but it is now fixed and CC p-pol lock was recovered.

Yuhang, Marc, Michael

We tweaked a lot of the infrared mode cleaner control loop, from optics to electronics.

Details

First of all, the power to the IRMC_REFL PD was decreased using an ND1 filter, since the voltage was near saturation. A lens was also placed to reduce the beam size on the PD.

We investigated a lot of connections coming from the photodetector and going to the servo board, cables, servo settings, DC blocks. The reference level for the IRMC error signal was about 1.2 V before the replacement of the main laser EOM, and right now we have 120 mV. By comparison, the SHG error signal only went down by about a factor of 4 after the EOM change. They each use the same PD (Thorlabs InGaAs RFPD PDA05CF2) so it seems that there was some other source of reduction. We scanned and fixed all of the settings of the IRMC servo board, particularly the servo gain, detection threshold and PZT scanning speed. Halfway through we had some trouble locking, so decided to check with SR560 instead of the servo, and indeed it could lock with quite low gain. However, for the servo the gain is not sufficient to provide a good signal. By slowing the scan speed on the servo and moving the scan window around using the PZT offset knob on the high voltage driver, it could be seen that the servo is attempting to lock with a flashing red light, so it is detecting the PDH signal and the reflected peak crossing the locking threshold.

Eventually we decided to consult Pierre Prat regarding the electronics board. We propose to replace resistor R33 of figure 1 which determines the amplification of the gain potentiometer.

We found the IRMC transmission was 1.28mW while it was about 2mW in the past.

We remove a quite transparent square ND filter and could recover about 1.8 mW transmission.

We tried to tweak a bit alignment (both PBS and lens before the IRMC) but it did not change the transmission.

Marc, Michael

We attempted to fix the CC PLL locking issue but no luck. It seems that the issue is on the electronics side as the optical level coming out of the fibers is quite good.

Details

I aligned a bit the ML->AUX2 fiber. I made about a 20% increase in the voltage on the oscilloscope coming from the fiber PD monitor. Then, we checked the couplings. The power levels are as follows:

ML in 4.6 mW

ML out 0.75 mW

ML coupling = 0.75*2/4.6 = 33%

ML scope 7.5 mV

CC in 1.0 mW

CC out 0.3 mW

CC coupling 60%

CC scope 2.0 mV

Seems like way too good CC fiber coupling and yet not much signal on the oscilloscope. I tried doing a full rotation of the waveplate in from the the CC fiber but it didn't change noticeably. I also tried switching PDs but the result was the same. Likewise, both PDs showed no appreciable signal on the spectrum analyser.

I tried calculating the expected voltage from the PD. The sensor is not transimpedance (Thorlabs DET01CFC/M) and the output voltage depends on the load resistance V_out = I_out * R_load. The current conversion is ~ 0.7 A/W at 1064 nm. We use 50 Ohm terminators, so the expected voltage would be about 26 mV for ML and 10.5 mV for CC. But the measured value is about a factor 4-5 below this. For comparison, the p-pol PLL has a total voltage of about 45 mV (~ ML 20 mV + ppol 25 mV).

[Marc, Shalika]

We modified the temperature controller VI to be able to change quickly the LC temperature.

Indeed, up to now the controller would disable if the requested temperature was too far from the actual one.

Now, we pause the controller for 2s to prevent the controller to disable. It is now far quicker to reach the requested temperature but there could be some issue with data saving during the pause.

Then, we measured the LC retardance as a function of its temperature with 0V applied.

As shown in attached figure, we varied the temperature between about 25degC to 45degC.

To fit over a broad temperature range, we used a*10 + (T-T0)*b + c*np.exp((T/T0)*d) (in blue).

As we mainly care about low temperature where we have the largest retardance, we also tried a 1st order polynom up to 30degC (in red).

We now have -16.2 nm/degC (the minus sign coming from the unwrapping).

We tried to fit with various function the LC retardation as a function of applied voltage.

Up to now we were using R = a + b/(1+(V/c)**d)**e (1pole in attached figure) but it seemed not optimal as seen from the residual shape.

We now tried the 2 poles function : R = a + b/(1+(V/c)**d)**e + b/(1+(V/f)**g)**h and 2 different poles : R = a + b/(1+(V/c)**d)**e + i/(1+(V/f)**g)**h.

These 2 functions improved a lot both residual rms and peak-to-peak values. We are now able to reconstruct the LC retardance better than for polarimetry.

New step is to add the temperature dependence.

I remeasured the transfer function whose resonant frequency is set around 0.5Hz.

I measured it from 2Hz to 0.1Hz.

The peak of resonant looks like 0.4Hz.

This time, peak of resonant is crushed by range of photo sensor.

When I measured it around resonant frequency, displacement is bigger than linear range of photo sensor.

What I did: measure transfer function of Roberts linkages.

I measured transfer function of Roberts linkages.

I attacehd two transfer function.

Resonant frequency are set at 1.5Hz(Fig 1, 2) and around 0.5Hz(Fig 3, 4) respectively.

The set up of these experiments are also attached.

The experiment whose resonant frequency is set at 1.5Hz probably have peak at 1.5Hz(Fig 1).

The peak on experiment whose resonant frequency is set around 0.5Hz is 3Hz(Fig 3). This peak is yaw motion.

The reason that I didn't measure transfer function surrounding resonant frequency is the range of photo sensor.

I realized that when I measure the transfer function, I need to measure mutiple time.

What I will do: I will remeasure the transfer function whose resonat frequency is set around 0.5Hz.

I remeasured the transfer function whose resonant frequency is set around 0.5Hz.

I measured it from 2Hz to 0.1Hz.

The peak of resonant looks like 0.4Hz.

This time, peak of resonant is crushed by range of photo sensor.

When I measured it around resonant frequency, displacement is bigger than linear range of photo sensor.

I tryed to check how much the shaker works.

I attached the pictures of the fransfer function from input of the shaker's power amplifiler to read out from the accelerometers' gain amplifiler.

The accelerometers are on the shaker's floor.

I didn't tune read out voltage from these accelerometers, so I only be able to refer the shapes of transfer function.

The shaker is MEE-035 made by Akashi Corporation (Fig 3).

The power amplifier for shaker is AME-100made by Akashi (Fig 4).

The accelerometer on shaker's floor are 707LFZ and 710B190 made by TEAC (Fig 5, 6). The manual says that these accelerometers have frequency response from 0.2Hz to 8000Hz and from 0.02Hz to 200Hz respectively.

The gain amplifier for accelerometer is SA-16P and SA-16U made by TEAC (Fig 7).

The input for power amplifiler is 1Vpp. The gain for accelerometer is 200 for 707LFZ and 10 for 710B190.

I set lowpass filter at 100Hz on the gain amplifiler for accelerometers.

I tuned accelerometer's resonat frequency to measure seismic noise and know the mechanics of accelerometer.

In this time, I tried to make resonant frequency be close to around 0.2Hz.

The pictured and transfer function was attached.

The weight attached accelerometer is 341.2g.

The transfer function is from actuator voltage to accelerometer's LDVT read out voltage.